The world's oldest working mechanical clock

3rd October 2024I have made a 3D model of the world’s oldest working mechanical clock.

In 2024, around the same time as a team of American scientists reached a technological breakthrough which will surpass the accuracy of atomic clocks with a new “nuclear clock” (which is so precise as to allow us to test whether our physical constants are in fact constant or not), I became interested in the very first mechanical clocks. I recently visited Salisbury Cathedral which has, pushed against a wall and surrounded by a barbed chain barrier, a 638 year-old clock. I can’t think of anything older that I’ve personally seen which moves - that this historical contraption has continued keeping time for 600 years is compelling and a bit esoteric. (This being only slightly undermined by the fact that the clock was broken during my visit – a snapped rope...more on that later)

This blog-post is going to document my curiosity-driven look through the techno-cultural relationship people have had with time over history – why do we keep time, how do we conceptualise it and technically how have we “kept time” through the years? I’ll explain exactly how the clock works and comment on why it was designed and built the way it was.

And yes, as a mechanical engineer, I decided to make a 3D CAD model of the entire clock mechanism. How hard can it be?

An incomplete history of timekeeping

Before we get to that though, let’s…go back in time.

The earliest clocks we know about are sundials. The movement of sun, moon, stars and the day/night and seasonal cycles are central to how early humans would have measured and conceptualised the passage of time. Being able to anticipate (not just react to) those changes provides humans and many other fauna a significant evolutionary benefit. This means we can be in the right place at night-fall, we can stock food and resources for winter and we can sow and harvest at the most optimal times of the year. But like no other organism, humans have opted to use technology to measure time rather than just relying on our internal sense of time and visual observations. Sun-dials then have a very direct relationship to the passing of time – the changing position of the sun in the sky directly indicates the time, or the angle of shadow on a dial allows a more accurate reading.

Sundials or other directly astronomical timekeeping methods have two big drawbacks: they can’t “do stuff”, but more importantly, they need to be in direct view of the sun. Apparently this was a significant enough problem to ancient Egyptians that they were motivated to develop an alternative technology (that would allow sacrifices to be carried out at accurate times in the night).

Water clocks were in use from at least 1500 BC in places like Egypt, Babylon, Syria, India and China. They work by filling or draining a vessel in a certain period – at the simplest, a vessel with a hole close to the bottom indicates time has passed when empty; at their most complex water clocks could be ornate and feature ancillary moving and/or sounding mechanisms. Water clocks have some advantages over sundials: they work indoors, at night and on cloudy days. They can also ‘do stuff’ by using mechanical elements, i.e. striking a bell or, I don’t know, rotating a celestial globe and causing mannequins to appear from behind doors and march around, or something. Water clocks (“clepsydra” – literally “water thief” in Greek) do have some fundamental limitations though. The flow of water (and thus passage of time!) is influenced by temperature and while inaccuracy is one thing, a clock freezing over or drying up is quite another (this was addressed in China by using Mercury as the driving fluid, but, well, that didn’t catch on). On the other hand simple water clocks were simple to make, transport and use – and were evidently accurate enough for society’s requirements until the 1200s. Water clocks also amusingly provided a ready supply of water for fighting fire.

The breakthrough for mechanical clocks as a technology happened somewhere in Europe at some time in the late 1200s and was the ‘verge and foliot’ mechanism. Mechanical clocks solved a number of problems for the likes of a cathedral. Because they didn’t need a large water reservoir, they were lighter, thus easier to integrate into a tower (and certain not to leak or go nasty). Recharging the clock meant winding weights back up, rather than pumping water back into a primary basin. They were also more accurate (~2 minutes error per day – 0.14% error!) and didn’t require heating to prevent freezing over in winter. With society becoming more ordered, with the Great Survey of the Domesday book completed in 1086 and Magna Carta laying the basis for civic law in 1215, accurate and reliable timekeeping was an important technical capability for maintaining organisation. The Salisbury Cathedral clock is believed to have been originally made in 1386 and is therefore a relatively early example of a verge and foliot mechanical clock, but though it would have been expensive and specialist to build it isn’t itself considered a breakthrough design, just an early surviving example.

The breakthrough for mechanical clocks as a technology happened somewhere in Europe at some time in the late 1200s and was the ‘verge and foliot’ mechanism

Before we move onto design and technology, a note on units of time. Different societies have conceived of and measured the passing of time; days, nights and seasons in different ways. Today we are familiar with the 60 seconds / 60 minutes / 24 hours / 365 days in the Julian calendar. A major functional benefit of this system is the number of divisible factors in each of 60, 12 and 360. That there is an analogy to angular degrees is important too, as revealed itself to me when modelling the Salisbury clock’s gears, where the number of teeth in each gear must be an integer (thus, divisibility being important) and there is a direct relationship between angular rotation, bell strikes and passage of time.

How it works

What you see when looking at the clock will not be familiar or immediately intelligible to most people - it has no clockface, no hands, does not provide a familiar “tick-tock” and is over a meter in all dimensions. It’s constructed of wrought iron, wood and rope. It’s held together not by screws or bolts but mortise and tightly-fitting tenon wedges (or cotters) that pull the pieces into each other. It’s powered by gravity, with two weights pulling rope over a pulley to steadily unwind drums to turn the mechanism. Timekeeping is handled by a reciprocating, spinning mass and time-telling is achieved by hitting a bell (the appropriate number of times to ring out the hour).

- The clock has two sets of gearing: the timekeeping mechanism and the striking mechanism which strikes the bell the correct number of times on the hour.

- Each mechanism has a separate energy source; a mass suspended by a rope and pulley. The timekeeping mechanism loses energy through friction; the striking mechanism loses energy also through striking the bell.

- The timekeeping mechanism unwinds a drum of rope progressively as the weight lowers; this rotation is stepped up to rotate the sawtooth gear termed “verge”, which collides alternately with the two “pallets” on the vertical foliot shaft, one colliding with the top of the verge spinning it first anti-clockwise (ha?), then after 90 degrees one colliding with the bottom of the verge to spin it back clockwise. The period of the resulting reciprocal motion is calibrated by the radial position of the two weights atop the foliot. Each single-direction period of rotation takes approximately 4 seconds

- The timekeeping weight’s descent having thus been slowed to a known rate, one full rotation of the timekeeping drum corresponds to 1 hour. A single pin on the main wheel attached to the drum lifts a release lever, rotating a bar that travels the length of the clock and releases two corresponding catches holding either side of the striking mechanism

- The striking mechanism now being released, the weight begins to fall, unwinding the drum. The rotation is stepped up through a series of gears to spin a “fly fan” which creates aerodynamic drag to slow the mechanism. Each 1/8th rotation of the drum causes one of 8 pins to lift a lever and thus pull down a chain attached to the clock’s bell hammer

- The number of strikes of the bell is governed by how far the striking mechanism is permitted to rotate before the catch drops back into a groove; grooves are spaced progressively further apart according to this need. When the striking weight’s descent is suddenly halted by this catch, the momentum built up in the fly fan is allowed to dissipate slowly through a ratchet mechanism

- When each drum is fully unwound or the weight has reached the floor, the mechanisms must be separately re-wound using the handwheels on each side. The potential for entrapment or pinching is significant and serious injuries are more than possible. To assist with re-starts, I believe a locking mechanism has been added at a later date to the fly-fan shaft (it appears to have screws) but I’m not sure!

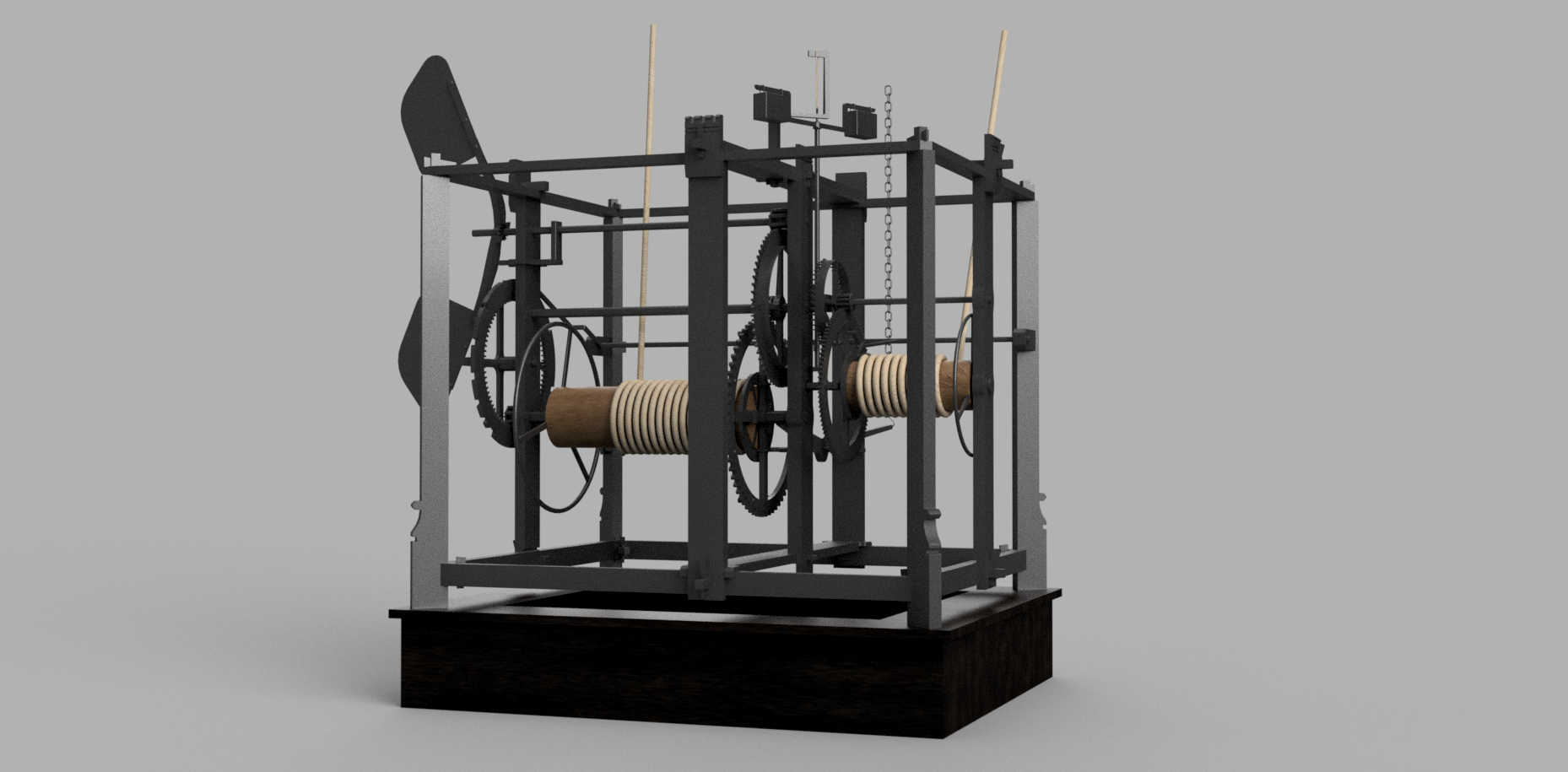

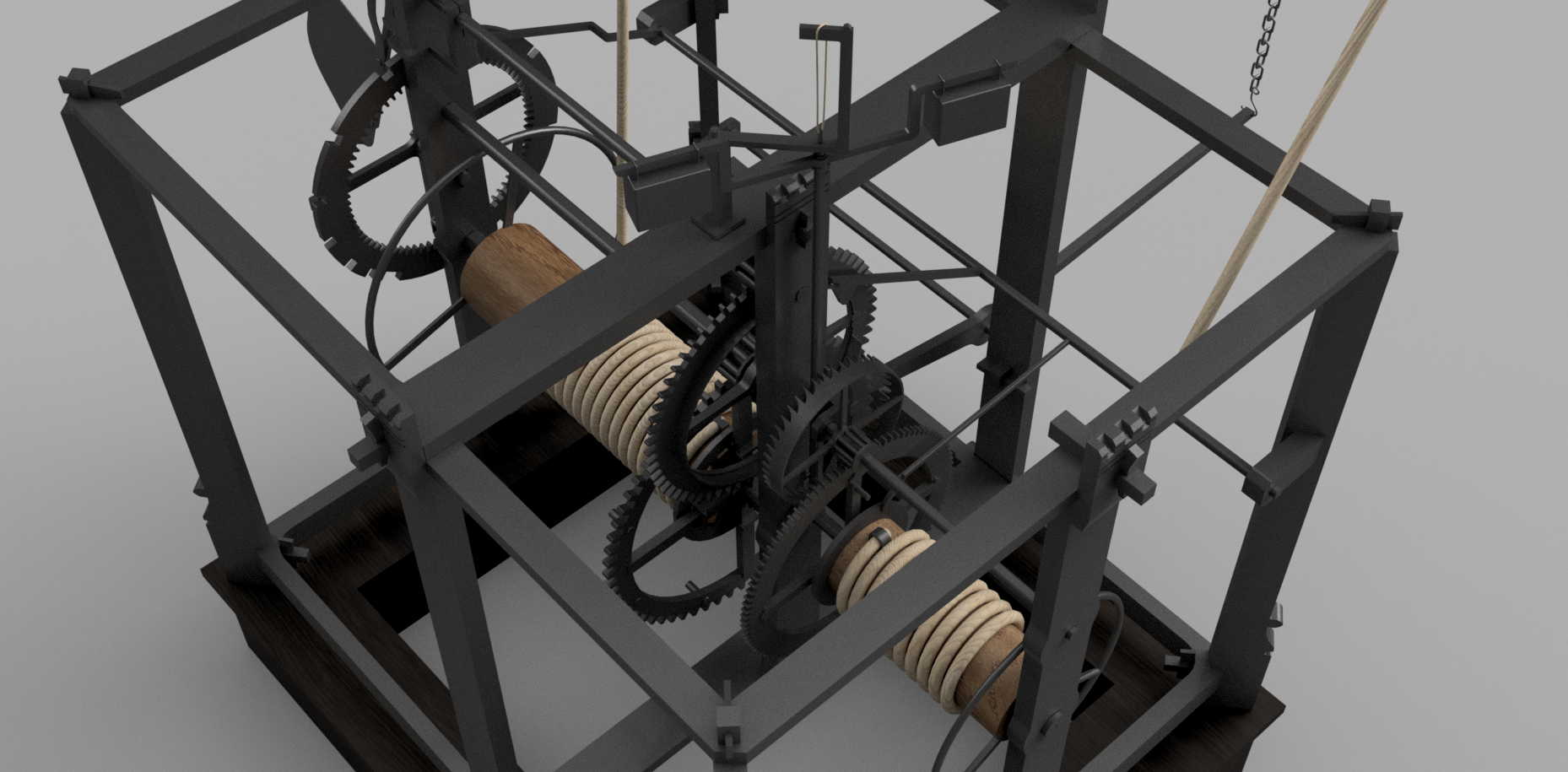

Above: Timekeeping mechanism visible on the right half, striking mechanism on the left half, both with drums wound with ropes holding a weight across wall-mounted pulleys. Click to open full-size.

Above: Timekeeping mechanism visible on the right half, striking mechanism on the left half, both with drums wound with ropes holding a weight across wall-mounted pulleys. Click to open full-size.

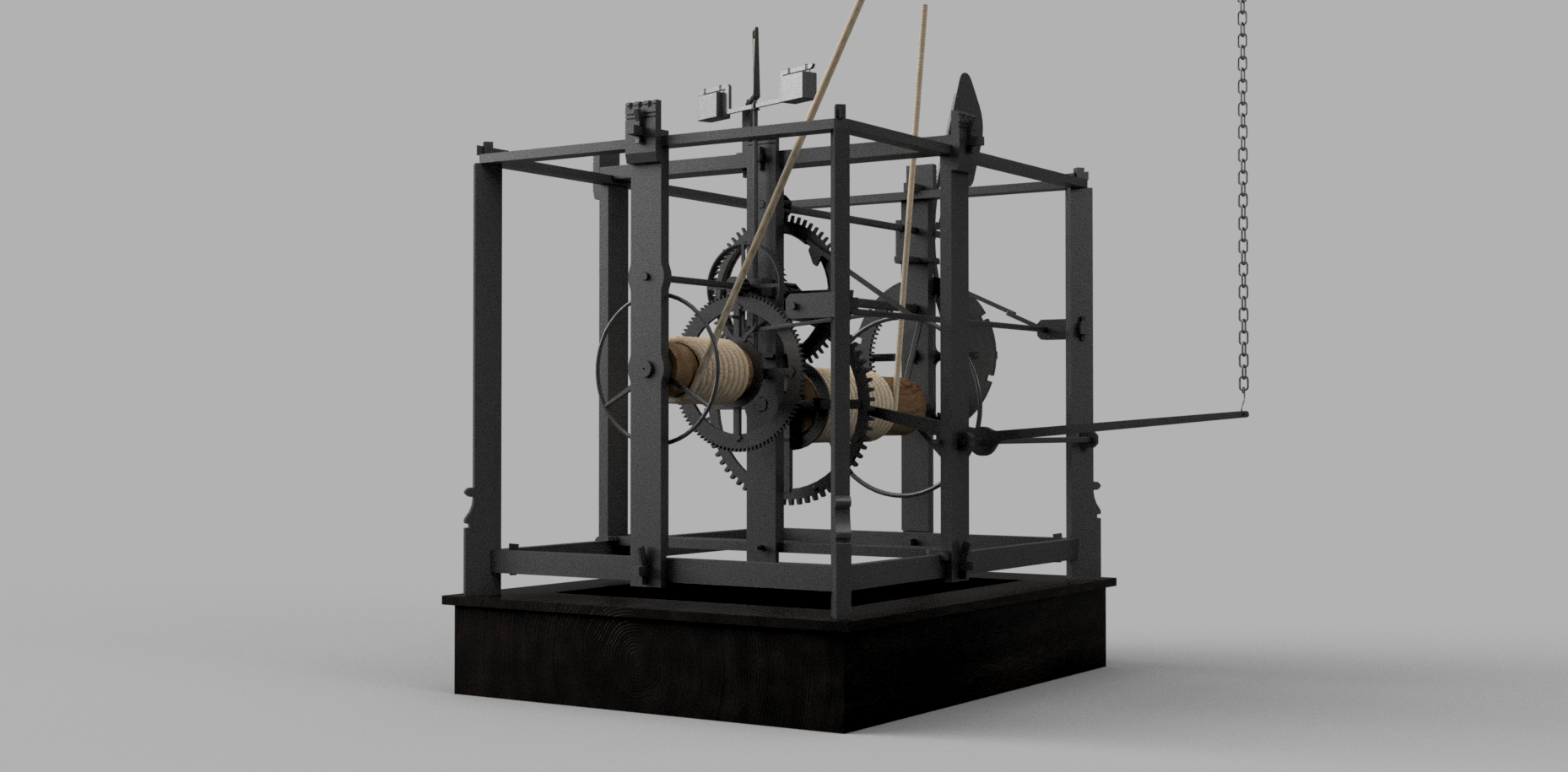

Above: View from the timekeeping mechanism side. The foliot is the main timekeeping component, which rotates with a reciprocal motion each 4 seconds. The foliot with two cuboidal weights are visible at the top of the frame. The chain connected to a long lever at the right is for striking the church bells, which would be mounted above the clock. Click to open full-size.

Above: View from the timekeeping mechanism side. The foliot is the main timekeeping component, which rotates with a reciprocal motion each 4 seconds. The foliot with two cuboidal weights are visible at the top of the frame. The chain connected to a long lever at the right is for striking the church bells, which would be mounted above the clock. Click to open full-size.

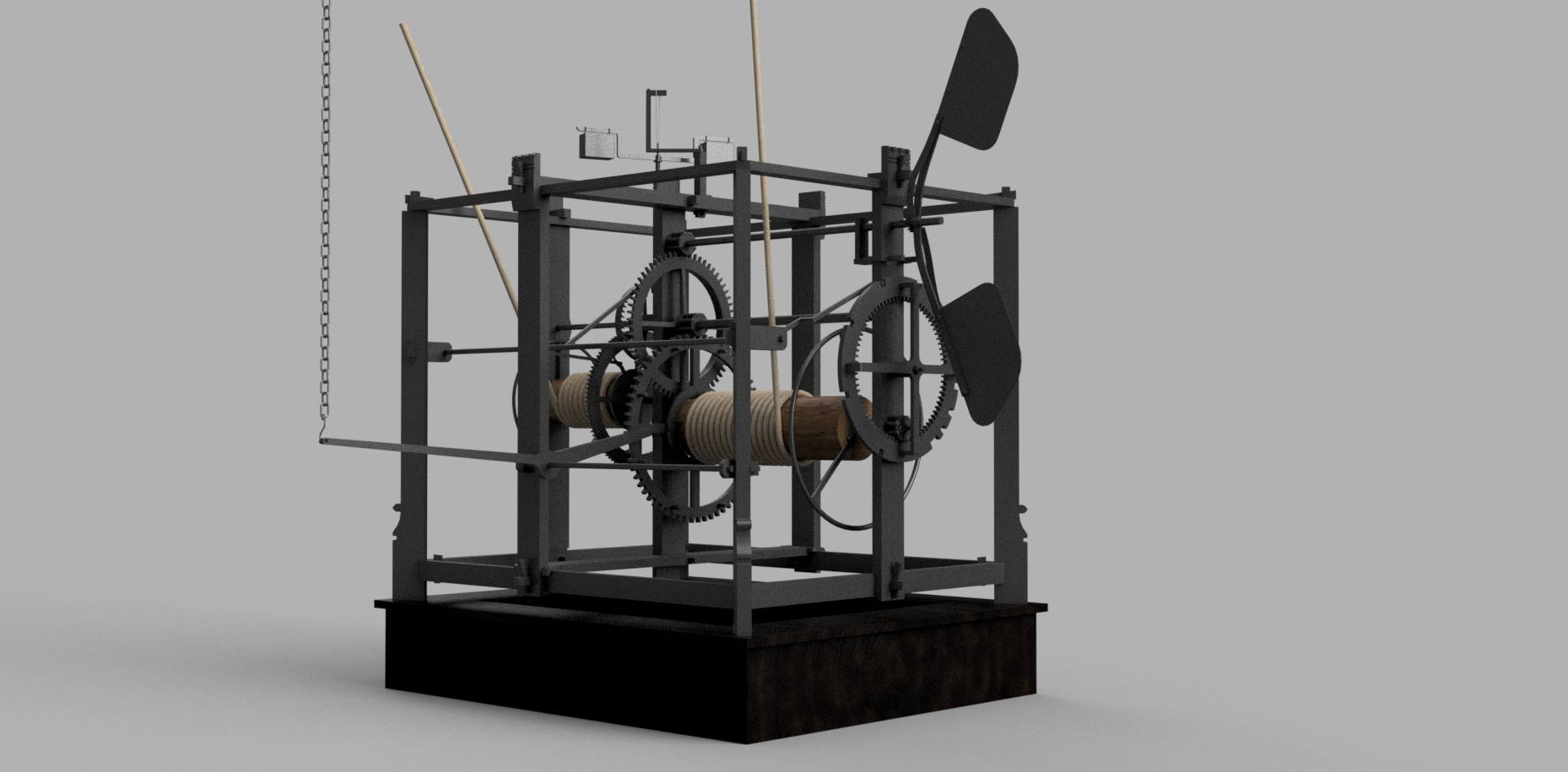

Above: View from the striking mechanism. The striking mechanism is held captive until the hour mark, when it is briefly released to toll the hour. The paddles at the upper-right serve the purpose of slowing the mechanism's rotation by creating air resistance. The plaque inscription, not shown, reads "DANGER PLEASE KEEP AWAY FROM THE FLY-WHEEL". For every sign, a story. Click to open full-size.

Above: View from the striking mechanism. The striking mechanism is held captive until the hour mark, when it is briefly released to toll the hour. The paddles at the upper-right serve the purpose of slowing the mechanism's rotation by creating air resistance. The plaque inscription, not shown, reads "DANGER PLEASE KEEP AWAY FROM THE FLY-WHEEL". For every sign, a story. Click to open full-size.

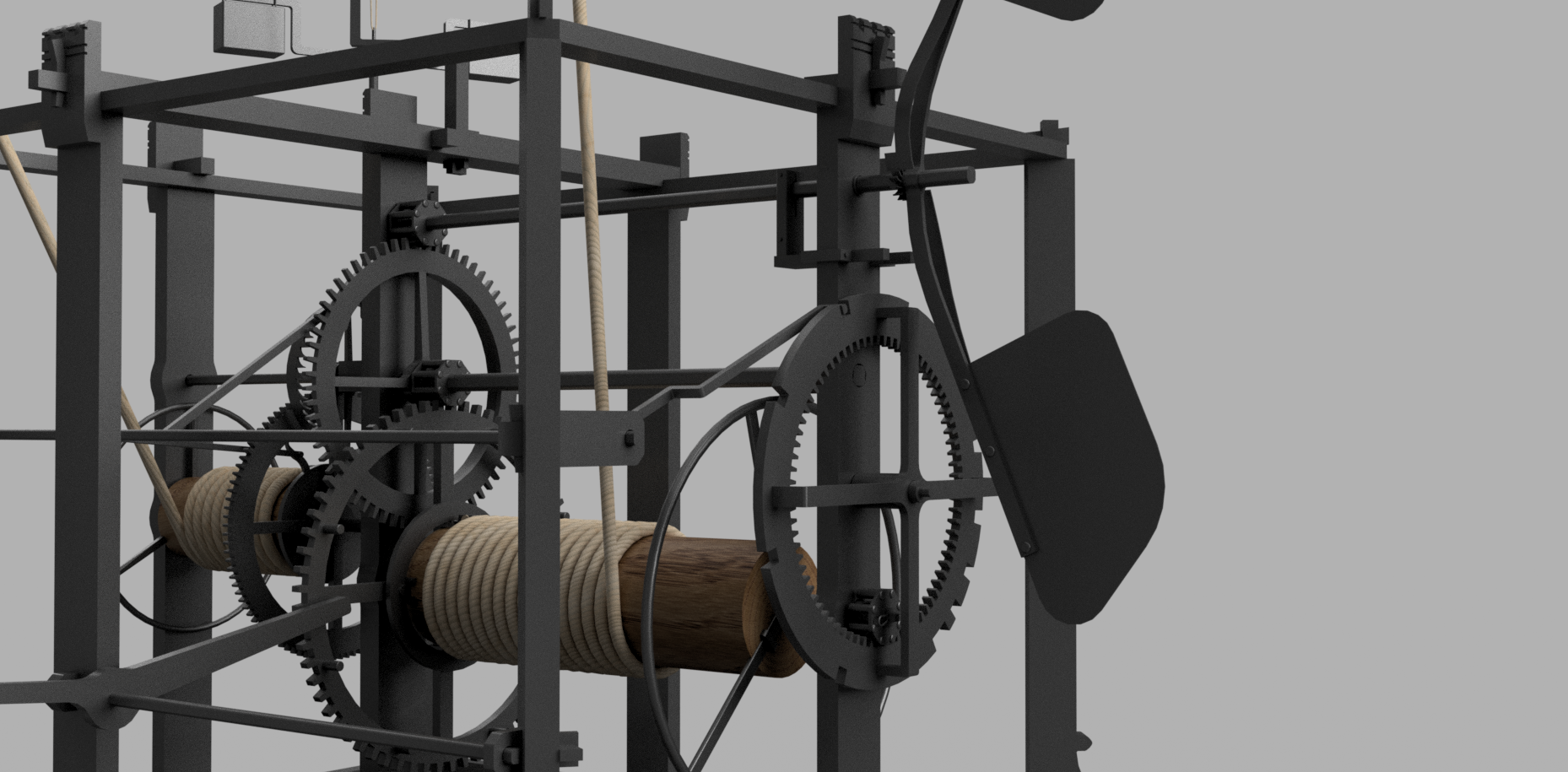

Above: Note the interesting counting wheel below the fly-fan, a large gear with 78 internal teeth and 11 notches around the external perimeter. The spacing of these notches progressively increments in order to permit the striking mechanism a greater number of rotations before the holding lever drops into the next notch, thus allowing more striks of the bell. The bell striking lever interacts with one of 8 pins around the main striking mechanism gear, to left of drum. You can also see the 64-to-8/64-to-8 step-up gearing from drum to fly fan shaft. Click to open full-size.

Above: Note the interesting counting wheel below the fly-fan, a large gear with 78 internal teeth and 11 notches around the external perimeter. The spacing of these notches progressively increments in order to permit the striking mechanism a greater number of rotations before the holding lever drops into the next notch, thus allowing more striks of the bell. The bell striking lever interacts with one of 8 pins around the main striking mechanism gear, to left of drum. You can also see the 64-to-8/64-to-8 step-up gearing from drum to fly fan shaft. Click to open full-size.

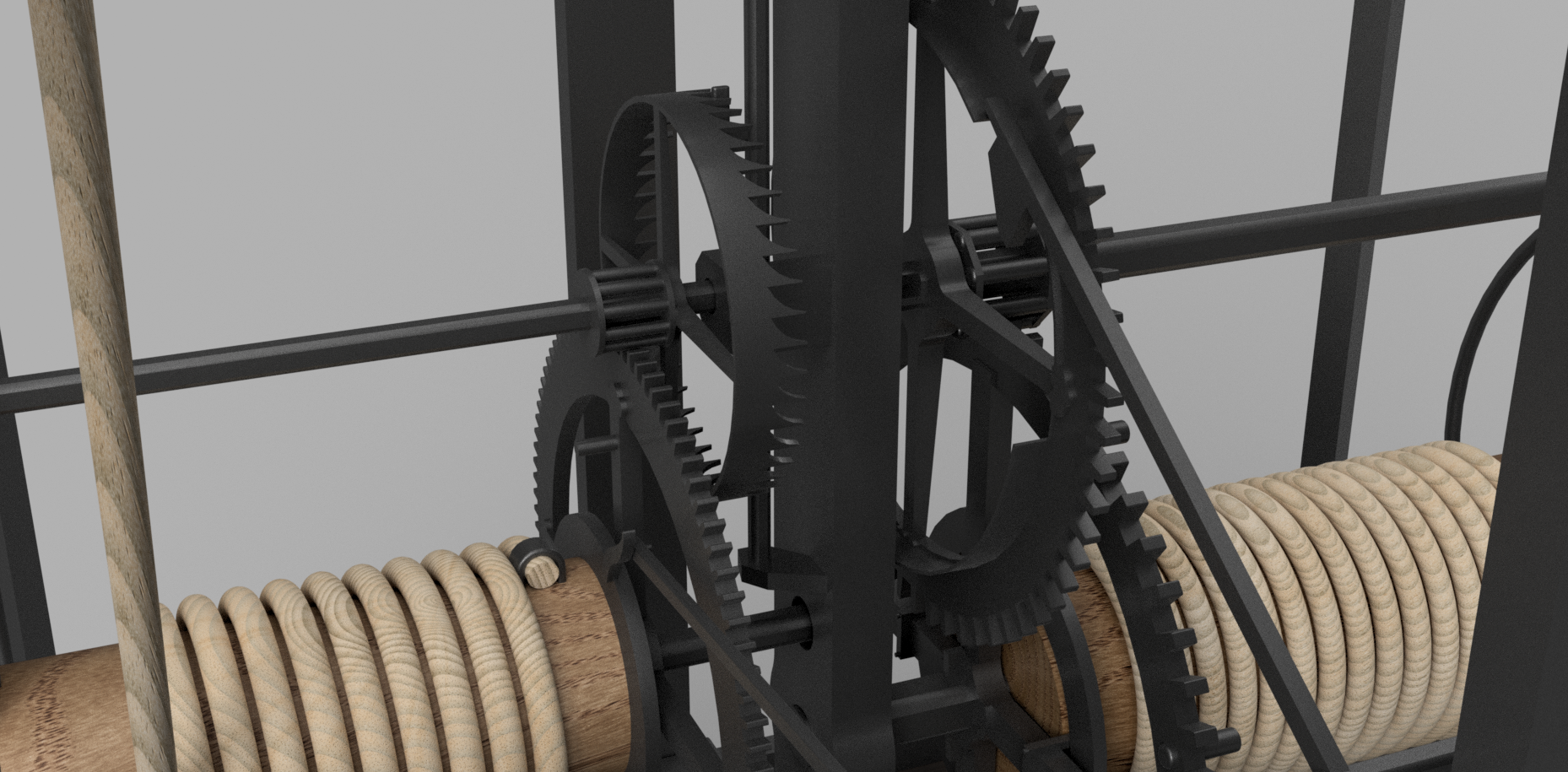

Above: The main time-keeping mechanism, the verge and foliot. The verge is the crown-like sawtooth gear. Difficult to see are two "pallets" protruding from the vertical shaft, which are about 90degrees apart. As the verge rotates, one pallet strikes the top of the verge, rotating the foliot shaft anti-clockwise. 90-degrees later, the pallet on the bottom of the verge is struck, sending the foliot back clockwise. This continues every 4 seconds until the rope is unwound! Click to open full-size.

Above: The main time-keeping mechanism, the verge and foliot. The verge is the crown-like sawtooth gear. Difficult to see are two "pallets" protruding from the vertical shaft, which are about 90degrees apart. As the verge rotates, one pallet strikes the top of the verge, rotating the foliot shaft anti-clockwise. 90-degrees later, the pallet on the bottom of the verge is struck, sending the foliot back clockwise. This continues every 4 seconds until the rope is unwound! Click to open full-size.

Above: The cuboidal weights either side of the foliot can be moved in or out from the center of rotation (like a spinning ballerina retracting or extending their arms) to adjust the clock's rate. The small loop of string above serves the function of a thrust bearing - reducing friction and perhaps smoothing the motion as well. Note the mortise and tenon wedge construction of the frame. Click to open full-size.

Above: The cuboidal weights either side of the foliot can be moved in or out from the center of rotation (like a spinning ballerina retracting or extending their arms) to adjust the clock's rate. The small loop of string above serves the function of a thrust bearing - reducing friction and perhaps smoothing the motion as well. Note the mortise and tenon wedge construction of the frame. Click to open full-size.

Design and manufacture

I believe the clock is made primarily in wrought iron due to the period of manufacture and the large dimensions of the metal; steel was not produced in large quantities until pioneering developments at Coalbrookdale, Shropshire in the early 1600s. Wrought iron has similar bending modulus (i.e. stiffness) to steels, around 190GPa, however about 50% lower tensile and compressive strength1. Due to the way wrought iron is worked, it has a linear grain, which makes it easily recognisable when broken or corroded. Due to this linear structure, wrought iron does not have the same strength in all directions, and this may account partially for the extremely large frame cross-sections; however I think the main factor is likely to be manufacturing limitations.

The joining technique of mortise and tenon gives the frame a wood-like appearance and the technique would surely have originated from woodworking. Screws would not be used in large quantities until the industrial revolution made it economical to manufacture to the repeatable and precise dimensions required for proper mating. Regarding the large size and weight of the frame, it's likely that a wooden scaffold or supporting structure of some sort was used during construction.

In general, the bearings are ‘plain’ i.e. without a ball or other friction-reducing technique. Before engineered synthetic lubricants became available in the mid 1800s, whale oil was the most common mechanical lubricant, however, I have no evidence either way as to whether any of the bearing surfaces are lubricated. A notable exception to plain bearings is the reciprocating foliot, which is suspended by a piece of string to reduce friction and perhaps also add a smoothing cyclical elastic store-release effect.

The birdcage gears are also interesting, I assume it was more straightforward to manufacture round bar which could be cut to length and used as teeth, rather than the manual grinding of small gear profiles. This would also add a level of common component between birdcage gears of varying dimension (the pinion on the timekeeping mechanism has 8 teeth while all pinions on the striking mechanism have 10).

Design and construction would have followed an artisanal pattern, using a fairly local supplychain for all materials, both primary and secondary and it’s likely that most, if not all, parts were fabricated together. This gave the artisan oversight of each part, and given the bespoke nature of the design, parts would have been measured and fitted directly to each other, i.e. rather than being fabricated according to dimensioned and tolerance engineering drawings as would typically be done today. That said, a mechanism of this complexity did not spring forth from imagination, part-by-part, given the complex interrelationships between components; drawing(s) or exemplar model(s) to copy must have existed to assist the craftsmen. Subassemblies, parts or at least details may have been borrowed from other products being produced in the company; it would be interesting to chart these technological crossovers between applications, both to and from clockmaking. A wikipedia contributor comments:

“In 1388, Bishop Ralph Erghum moved from Salisbury to Wells … where he had installed a clock in 1386. He may have brought his clockmakers with him to Wells. The two clocks are almost identical in construction, although the Wells clock shows some improvements and additions”

Many forms of religious design and construction, for example carving stone or wood, took on a symbolic value in the Gothic period and became almost a form of worship in the act of devoting creative labour in the service of God’s church. Whether that would have extended to the design and construction of machinery like clocks I don’t know – but surely there is a philosophical angle to the human creation of a device which measures God’s creation in such a technical manner that could not have been lost to the Bishops who commissioned them (in this manner I’m now considering this project to be one of worshipful “gothic CAD”). Presumably this was seen as worshipful not blasphemous. As an aside, the “intelligent design” argument by William Paley which uses a watch as an example of the most intelligent product of man wasn’t written until 1802 – so in 1386 a mechanical clock (though admittedly not a watch) must have seemed very intelligent, or even magical, being so much less intuitive than a water clock. The Cathedral’s relationship to the clock appears to have been purely functional and practical though – it served an administrative function of keeping clergy and worshippers punctual and allowing prayer to be observed at canonical hours. Psalm 119 verse 164 states:

“Seven times a day do I praise thee because of thy righteous judgments.”2

I do think a large number of people, time and resources would have gone into producing the clock; it has well over 200 parts, some requiring extensive and careful finishing (e.g. gears) to fit and function properly, and may have required multiple time-consuming tries to achieve an adequate part. Looking at resources, from my model I can estimate that the clock is made from approximately 1,000kg wrought iron. Out of interest I decided to look into the effort it would have taken to produce this quantity of material and thus gain an insight into the scale of the supplychain. One kilogram of iron takes approximately 25MJ of heat to produce, and conveniently, charcoal has an energy density of 30 MJ/kg, thus, assuming a poor efficiency of 20-40%, I estimate that somewhere between 2,000 and 4,000kg of charcoal would have been consumed to produce the Salisbury clock, as well as the 1000kg+ iron ore itself. Incidentally, charcoal would likely have been used as a fuel rather than coal; coal (in purified state called coke) did not replace charcoal as the main fuel for smelting iron until early 1700s 3, although “sea coal” was used increasingly from the 1100s.

To explore this further, The Food and Agriculture Organization break charcoal production into the stages of Growing the fuelwood, Wood harvesting, Drying and preparation of wood for carbonisation and Carbonising the wood to charcoal. They use a ‘wet’ fuelwood to charcoal conversion ratio of 5 and 7 times, thus expanding my estimate to 10,000 to 28,000kg of collected fuelwood. Wet fuelwood has a typical density of 750kg/m3, thus taking the average of my range, equating to 25m3 fuelwood. 1 ha in tropical high forest yields ~90m3 by clear-cutting, meaning somewhere (very roughly) in the region of 2,500m2 – a forested area 50 meters by 50 meters which would presumably have been sourced locally and perhaps with arrangement by the church. My point is that this primary material production would have required a significant workforce and associated resources in itself. But please, check my calculations.

Lessons in long-term design

Given the visible robustness and impressive age of the clock I’m interested in what we can learn from its design. But to be clear, this clock will not tick-tock blindly past the demise of human civilisation into the great peaceful unknown where the passage of time is as well measured in aeons as in seconds. Rather, in the short 600 years the Salisbury Cathedral clock has been in use it has been maintained and modified frequently and periodically. Weights must be re-wound, ropes snap (as I saw on my visit) and the little piece of string which comprises a thrust bearing on the verge must surely require frequent attention. I’d guess that the foliot weights need adjustment every now and then. Though the clock is robust and relies entirely on high-friction plain bearings, wear it does, and close inspection reveals erosion on the gear teeth. But, requiring maintenance is not necessarily a barrier to enduring lifespans. Maintenance can easily become effectively impossible when it depends on things outside our control like software support, international supplychains for complex spare parts or external infrastructures like the internet or even access electricity; yet basic metalwork and spare rope rely on little externality.

This provides me an opportunity to bring up a highly relevant project happening today along many of the same themes – the Clock of the Long Now. Out in Texas, USA a team are constructing a clock which they hope will last 10,000 years. The objectives are to act as an exemplar project for considerate and long-term design, intergenerational empathy and thus hoping to instil the sort of perspective we sorely need to tackle big and long-term issues like climate change. Specifically, the sort of engineering challenges a 10,000-year clock will face are galvanic corrosion (i.e. the erosion of dissimilar metals), fusing of slow-moving metal parts (as a result of which, all bearing surfaces are to be ceramic) but also human issues like theft or negligence. It seems to me that we more often lend engineering time to producing short-sighted "things" which create long-term products like waste, pollution and toxicity or radioativity. I will comment that the machine is planned to play a unique chime every day for 10,000 years according to rules composed by Brian Eno, the mechanical computer for which Charles Babbage would have lusted, but the maintainability of which is questionable. Anyway, interestingly, some of the design principles penned by the Long Now foundation are highly relevant take-aways:

- Stay clean and dry

- Allow inspection

- Expect restarts

- Use familiar materials

- Make it easy to build parts

- Separate functions

Now, I'm not trying to claim the salisbury clock as a sort of design icon we can all draw direct inspiration from, but 600 years is a long time so let's give credit where it's due. Significant credit surely rests with the Salisbury Cathedral which, as a well-established institution was able to protect and maintain the clock (and also lose it for several hundred years, which was probably longeivity-positive). The clock also has no real theft value bar scrap metal, so we're lucky it was already recognised as a significant cultural artifact during WWII...

Inspection, separate functions and familiar materials are where the clock excels. Due to the large scale of the mechanisms, the simple construction methods and fact that all functions/component interactions are readily visible (no functions are concealed from view, and with no electronics or software, all functions can be deduced by visual inspection) the clock is reasonably straightforward to reverse engineer and modify. That said, the weight and fastening methods makes moving or significantly disassembling the clock a daunting task and while the oversized wrought-iron construction has mostly resisted wear, it can’t reasonably be considered the best way to design a clock which will last centuries; but perhaps it was at the time, given the materials and manufacturing techniques of 1386. But what were the design objectives and “lifetime” considerations for the clock in 1386? While I can’t imagine the artisan manufacturers considering the design to be final for all time, you would be hard pressed to identify any “planned obsolescence” in the design or even evidence of a practical “design life” – maintenance provided, the clock can certainly outlast our human time-horizon. They would also have known the likely failure points from similar previous clocks and thus a level of consideration would have gone into maintainability.

Comments on the method and meaning of reverse engineering

In terms of my project reverse engineering and then 3D modelling the clock, I have a few comments to make. I have quite a bit of experience in reverse engineering, but still that I can do this at all from 10 photos, a couple youtube videos and the information I can find online (notably the tooth number for each gear, unfortunately no gear measurements) demonstrates the relative simplicity of the mechanisms and the spaciousness between them. I first did my wikipedia research and studied photos before drawing a roughly-to-scale orthographic schematic. Normally, this is where measurements would be taken but as that wasn't an option, I had to proceed by eye - this probably made the whole thing possible rather than being bogged down in detail. It took me approximately 30-40 hours of focussed CAD modelling and that is allowing of the corners I have cut to strike a balance between accuracy, pragmatism and my available information. This obviously would be significantly more challenging for any modern clock.

But why do this at all? By re-creating, physically or digitally, existing arifacts we are able to interrogate so much more about then than is obvious on inspection alone. I think it’s also important to remember that our ancestors 600 years ago and long before were just as intelligent, motivated and creative as we are today and that our contemporary technology owes a debt of gratitude to millennia of development. It also reminds me that what a society chooses to design, invent or manufacture (or at least, what comes to prominence) responds to societal needs, rather than the other way around. Carrying out such reverse engineering exercises can allow us to learn more about historical technology and the intersection with societal concerns and priorities, thus perhaps illuminating, through contrast, those of today.